Unlocking Business Success with the China Rapid Prototyper in Metal Fabrication

In today's highly competitive manufacturing landscape, businesses are continually seeking innovative solutions to accelerate product development, reduce costs, and enhance quality. At the forefront of this revolution is the China rapid prototyper, an advanced technology that has transformed the way companies approach metal fabrication. With its unparalleled speed, precision, and affordability, the China rapid prototyper empowers metal fabricators and manufacturers to meet market demands efficiently and effectively.

Understanding the China Rapid Prototyper: A Game-Changer in Metal Fabrication

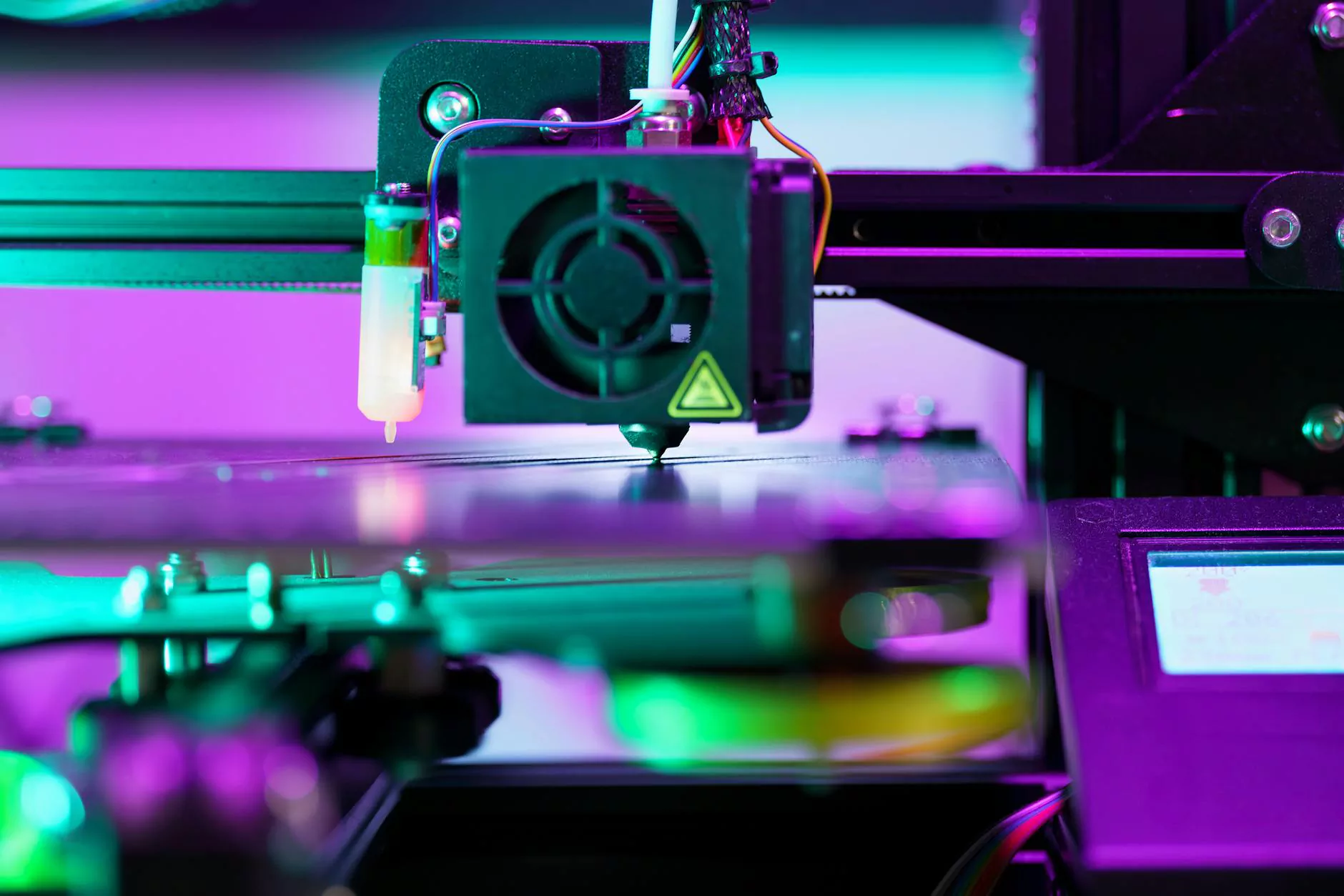

The China rapid prototyper refers to cutting-edge additive manufacturing machines developed and perfected in China, capable of producing complex metal components rapidly. This technology utilizes sophisticated processes such as metal 3D printing, selective laser melting (SLM), and direct metal laser sintering (DMLS), enabling the creation of prototypes with superior detail and mechanical properties.

Unlike traditional manufacturing methods, which are often time-consuming and costly, the China rapid prototyper offers a fast-track path from concept to physical object. Especially within the Metal Fabricators sector, this technology stands out as a critical tool for innovation, quality assurance, and product iteration.

Key Advantages of the China Rapid Prototyper for Metal Fabrication Businesses

1. Accelerated Development Cycles

By drastically reducing the time required to produce initial prototypes, the China rapid prototyper shortens development cycles. Companies can move swiftly from design to physical testing, enabling faster feedback and improvements. This agility allows manufacturers to stay ahead of industry trends and meet tight deadlines.

2. Cost-Effective Production

Traditional metal manufacturing involves expensive tooling, molds, and extensive labor. The China rapid prototyper minimizes these costs by enabling on-demand production without costly tooling. This is particularly beneficial for small-batch runs, custom orders, and complex geometries that are difficult to produce with conventional techniques.

3. Superior Design Flexibility

The additive nature of the china rapid prototyper allows for the creation of intricate internal channels, complex geometries, and customized features that traditional methods struggle to achieve. This opens up new possibilities in product design, leading to innovative solutions that stand out in the market.

4. Enhanced Material Options and Properties

Modern china rapid prototyper machines support a wide range of metal materials, including stainless steel, aluminum, titanium, and alloys. These materials exhibit excellent mechanical strength, corrosion resistance, and thermal stability, making the prototypes suitable for functional testing and even final production.

5. Quality and Precision

With advanced laser controls and high-resolution printing capabilities, the China rapid prototyper delivers components with exceptional detail and dimensional accuracy. This high quality ensures reliable performance in real-world applications and reduces the need for rework or extensive testing.

The Role of the China Rapid Prototyper in Modern Metal Fabrication

The integration of the china rapid prototyper into metal fabrication workflows is redefining industry standards. Here are some specific ways this technology influences modern manufacturing:

- Rapid Prototyping and Proof of Concept: Quickly bring innovative ideas to life for testing and validation, reducing time-to-market.

- Customized and Low-Volume Production: Economically produce small batches or customized parts tailored to specific client needs.

- Complex Assembly Integration: Fabricate complex assemblies in a single piece, reducing assembly time and costs.

- Design Optimization and Innovation: Experiment with new geometries and materials to push the boundaries of product innovation.

- Material and Engineering Research: Enable research teams to experiment with new metal combinations and structural designs rapidly.

Why Chinese Technology Leads in China Rapid Prototyper Development

China has rapidly developed its manufacturing and technological sectors, establishing a competitive edge in china rapid prototyper machines. Several factors contribute to this leadership:

- Advanced Manufacturing Ecosystem: A dense network of suppliers, research institutions, and manufacturing hubs facilitates continuous innovation and cost reduction.

- Investment in R&D: Significant investments in research enable Chinese companies to develop state-of-the-art metal 3D printing and fabrication equipment.

- Economies of Scale: High production volumes reduce costs, making their china rapid prottyper solutions more accessible worldwide.

- Quality and Standards Improvements: Chinese manufacturers have adopted global quality standards, ensuring reliability and performance of their equipment.

- Competitive Pricing: Cost advantages make Chinese china rapid prototyper machines attractive options for startups, small enterprises, and large corporations alike.

DeepMould.net: Your Partner in Metal Fabrication with the China Rapid Prototyper

As a leading industry player, deepmould.net specializes in integrating cutting-edge metal fabrication solutions, including the china rapid prototyper, into your manufacturing processes. Our goals are to enhance efficiency, improve product quality, and support your growth ambitions.

Whether you're in product design, small-batch manufacturing, or R&D, our expertise ensures that you leverage the full potential of this transformative technology. We offer comprehensive consulting, machine procurement, and technical support to help you harness the power of china rapid prototyping for metal fabrication.

Applications of the China Rapid Prototyper Across Industries

The versatility of the china rapid prototyper allows it to serve multiple industries, each with unique demands. Some prominent applications include:

- Automotive: Rapid development of complex engine parts, custom fixtures, and lightweight structures.

- Aerospace: Production of high-strength, lightweight components requiring precise tolerances and superior material properties.

- Medical: Customized implants, surgical tools, and prosthetics with intricate geometries.

- Consumer Electronics: Small-scale production of precision parts for gadgets and devices.

- Industrial Equipment: Manufacturing durable components with complex internal features for machinery and tools.

Future Trends in Metal Fabrication with the China Rapid Prototyper

As the technology matures, several exciting trends are poised to shape the future of metal fabrication:

- Hybrid Manufacturing: Combining additive and subtractive processes for enhanced precision and surface finish.

- Material Innovations: Development of new metal alloys specifically designed for 3D printing to improve performance and reduce costs.

- Automation and AI Integration: Leveraging automation and artificial intelligence to optimize printing parameters, quality control, and workflow management.

- Environmental Sustainability: Using recyclable materials and energy-efficient processes to minimize environmental impact.

- Global Adoption: Increasing adoption of Chinese china rapid prototyper technology worldwide, making high-quality metal prototypes more accessible.

Conclusion: Embracing Innovation with the China Rapid Prototyper

The china rapid prototyper is not just a technological advancement; it's a strategic asset that can significantly elevate your business in the competitive realm of metal fabrication. By enabling faster development, reducing costs, and expanding design possibilities, this technology aligns perfectly with the goals of modern manufacturers seeking agility and excellence.

Partnering with experienced providers like deepmould.net ensures that your company stays at the forefront of innovation, leveraging Chinese expertise and technological advancements to unlock new levels of success.

Invest in the future of metal fabrication — embrace the China rapid prototyper today and propel your business toward unmatched growth and innovation.